During the design and prototyping phase of the development of your part, small details can give you a better feel for reality by choosing the right RP Process. In this example, we have a snap and lock feature with 2 different rapid prototype processes and materials. as you can see and feel the softer option SLA (Acura 25 from 3D systems) was chosen over the stiffer Black PLA FDM sample. This gave us a better understanding of how the part would be inserted with production olefin in production. As you know, each part has its own set of requirements and it is our job to help you reduce risk before going to tooling on your part.

Stereolithography or “SLA” is a form of 3D printing technology used for creating prototypes or patterns by shooting a laser into a photochemical reactive liquid resign. the process builds layer by layer as the cured portion of the part is submerged below the liquid surface. SLA is one of the most dimensional accurate 3D printing processes and is used for cosmetic samples quite often.

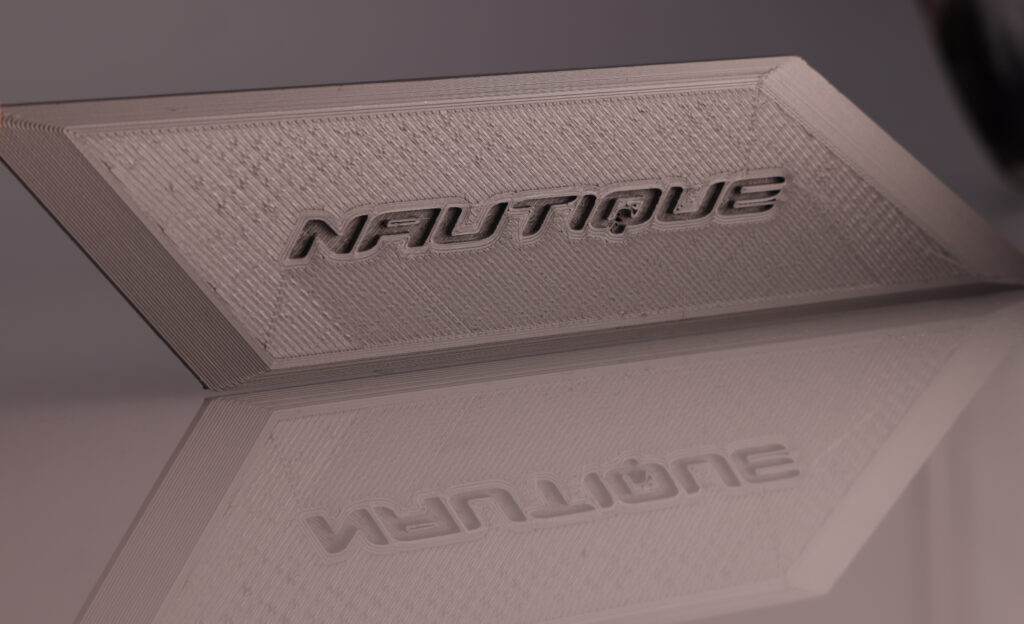

Fused Deposition Modeling or “FDM” is now the most widely used form of 3D printing technology. It is also used for creating prototypes or patterns but does this by extruding filament and depositing the material layer by layer in builds. Supports that are later broken away are added under unsupported geometry that is suspended. This process builds layer by layer as the melted layer portion of the part is cooled to a solid. FDM benefits are that it is fast, and a number of thermoform materials can be used to simulate an array of prototype options. Major advancements have recently come out of FDM where hobbiest and designers can easily afford the equipment and maintenance cost which was previously unattainable.

Selective Laser Sintering or “SLS” is yet another. is an additive manufacturing technique that uses a laser as the power source to sinter or Fuse powdered material (typically Nylon, aiming the laser automatically, at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to Selective Laser Melting; the two are instantiations of the same concept but differ in technical details. SLS (as well as the other mentioned AM techniques) is a relatively new technology that so far has mainly been used for rapid prototyping and for in rare cases full production of component parts. Production roles are slightly expanding as the commercialization of additive manufacturing technology improves.