Current approaches to new product development technologies related to part design, mold design, and plastic injection processing generally lack business-to-business collaboration tools that can facilitate accurate time and cost estimates based on a customer’s specific needs and their own circumstantial change. As we all know existing tools generally lack transparency in cycle time and material cost detail, often creating a lack of trust between product designers, purchasing agents, and business leadership decision-makers. Moreover, current approaches require substantial calculation time and are prone to errors commonly exhibited between part development, quoting, and part purchasing activities. We couldn’t agree more that there is indeed a need for a customized, confidential, internal, business collaboration tool that develops accurate predictions, higher confidence, and real-time feedback related to the part geometry, material, and mold options during product design and investment decisions.

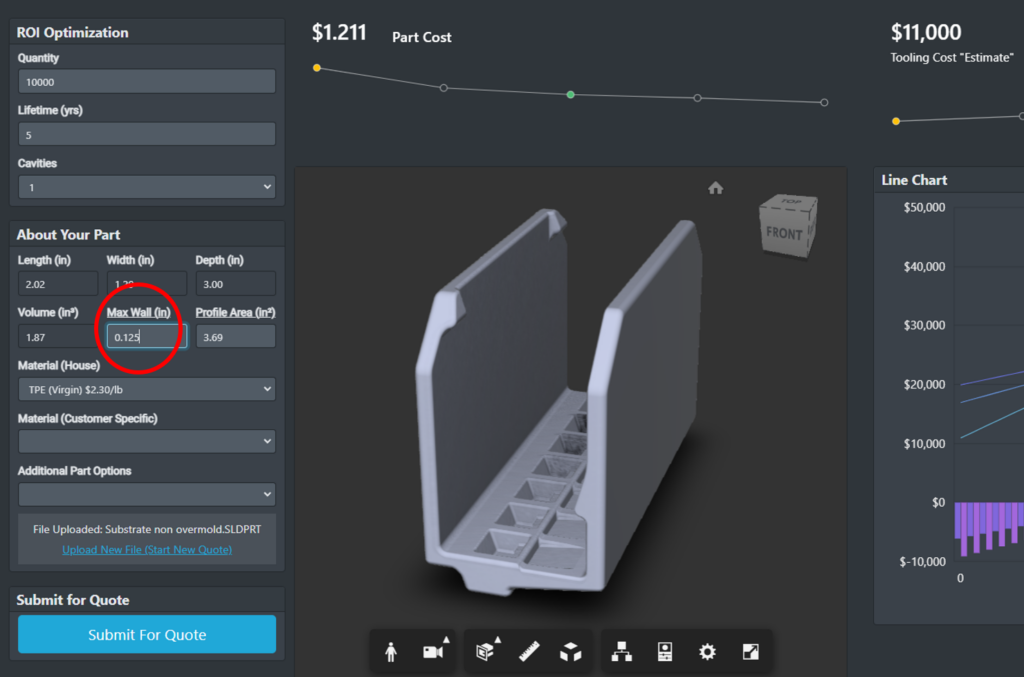

Obtaining a supplier price quote for an injection molded part is a very complicated and time-consuming task for engineers, purchasing agents, and supply manufacturers looking to develop an optimized financial business model. Such quotes typically include part cost, mold cost, and lead time. Changes to the part design, mold design, and material, introduce a host of financial and processing ramifications that have traditionally been calculated only by a downstream vendor or service provider with enough knowledge to quote. Typical lead times for custom injection molded part quotes can range from 1 day and up to 2-3 weeks. During the waiting period, the product development team is in question, confidence in part price and project success is “on hold” and teams are paralyzed, as new product introductions are held hostage ultimately wrinkling the momentum of a new idea, product, or cost savings initiative.

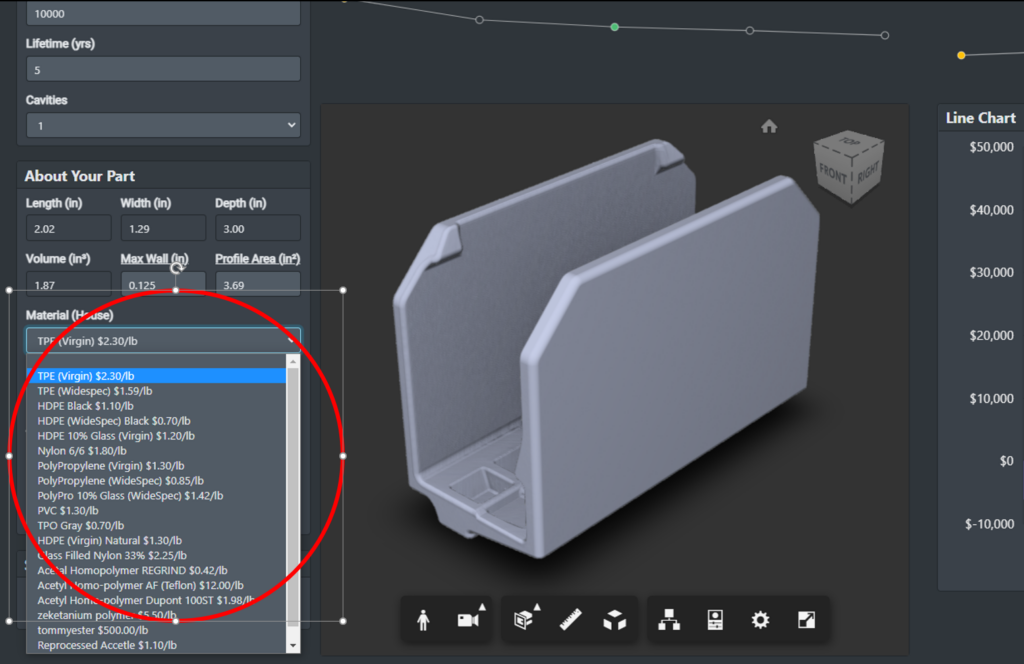

In injection molding, factors such as clamp force requirement, cavitation, cost of material, specific gravity material type or consumption of parts can change the mold and part cost dramatically. While the effects of one combination of these factors may be realized by one user, they may not be realized by another user on the same team depending on each user’s knowledge of the input factors’ contributing weight to the production processes optimization. Changing these variables can take weeks during the new product development cycle. When these changes are realized, developers can easily change the trajectory of a proposed new product introduction. Understanding these changes becomes painful as designers and purchasing agents wait for pricing updates based on changes.

The Polyestimator addresses the above issues by providing a customized trust-based tool with transparency regarding manufacturing costs and eliminates painful time delays and uncertainties during the formal mold and part quoting processes. Our Mission is to reduce the painful operations in the product development cycle so you can concentrate on ideas and implement financially feasible parts.

REDUCE COST AND OPTIMIZE YOUR DESIGN

GET STARTED

Reach out to us and get full access to our Polyestimator!