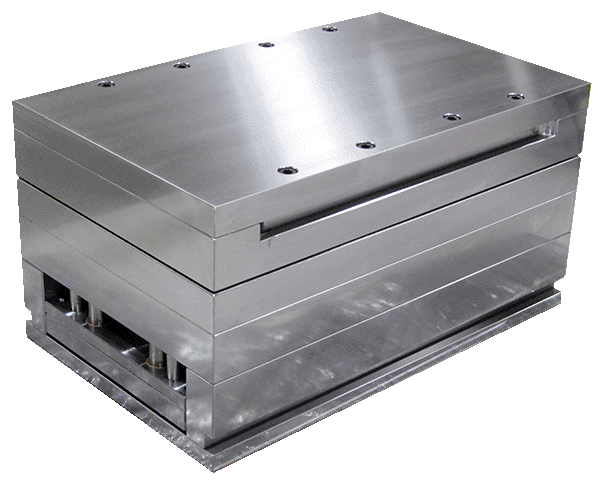

DEDICATED P-20 STEEL

1 MILLION PARTS

UNDERSTANDING THE DETAILS OF THE MOLD BUILDING PROCESS IS IMPORTANT FOR BOTH EVOK and YOU THE CUSTOMER. BECAUSE THERE ARE ALWAYS TIMELINE RISKS ASSOCIATED WITH BUILDING YOU A BEAUTIFUL MOLD, WE WANT TO BE TRANSPARENT IN THE PROCESS TO HELP YOU UNDERSTAND WHERE THINGS ARE AT WHEN A DELAY OR ENGINEERING CHANGE IS REQUIRED. ALTHOUGH WE MINIMIZE MOST RISK DURING THE QUOTING PHASE, EVERY PART IS DIFFERENT, THUS EVERY MOLD IS DIFFERENT IN TECHNICAL CHALLENGES.

STEPS TO COMPLETING YOUR INJECTION MOLD

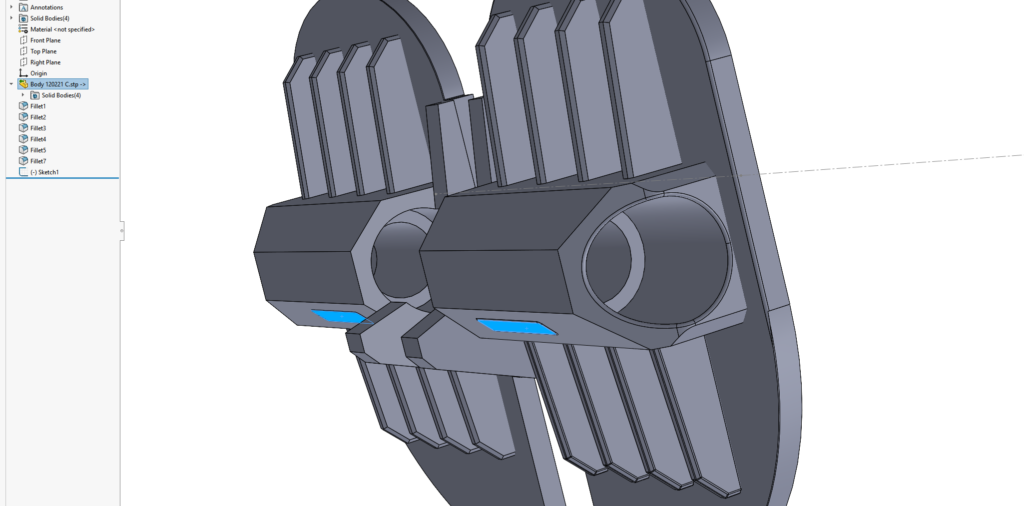

PLASTIC PART MODEL – PRINT APPROVAL

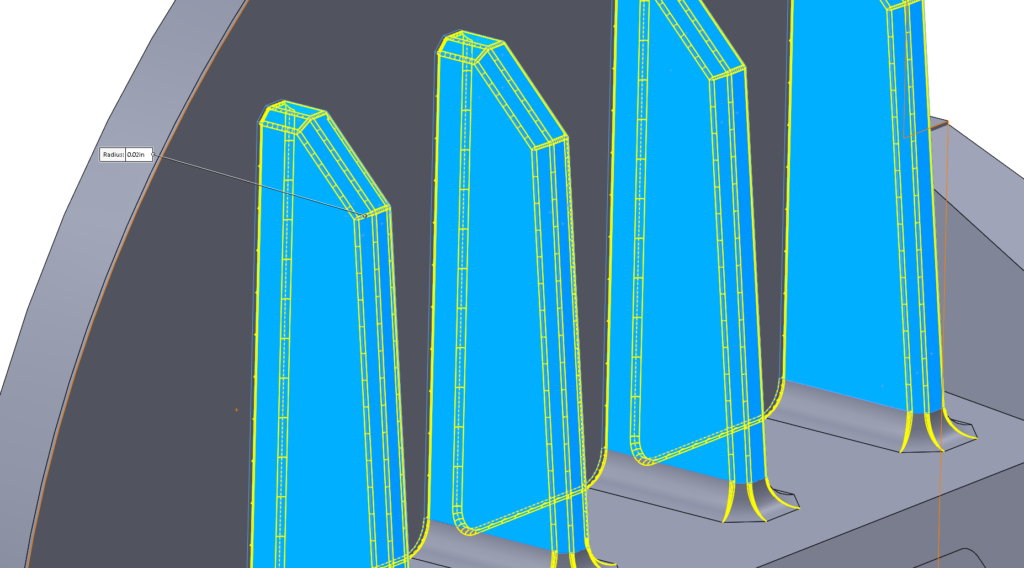

DFM INDICATING LAST MINUTE CHANGES

2D MOLD DRAWING APPROVAL

OPTIONAL FINAL DESIGN CHANGES BASED ON DFM

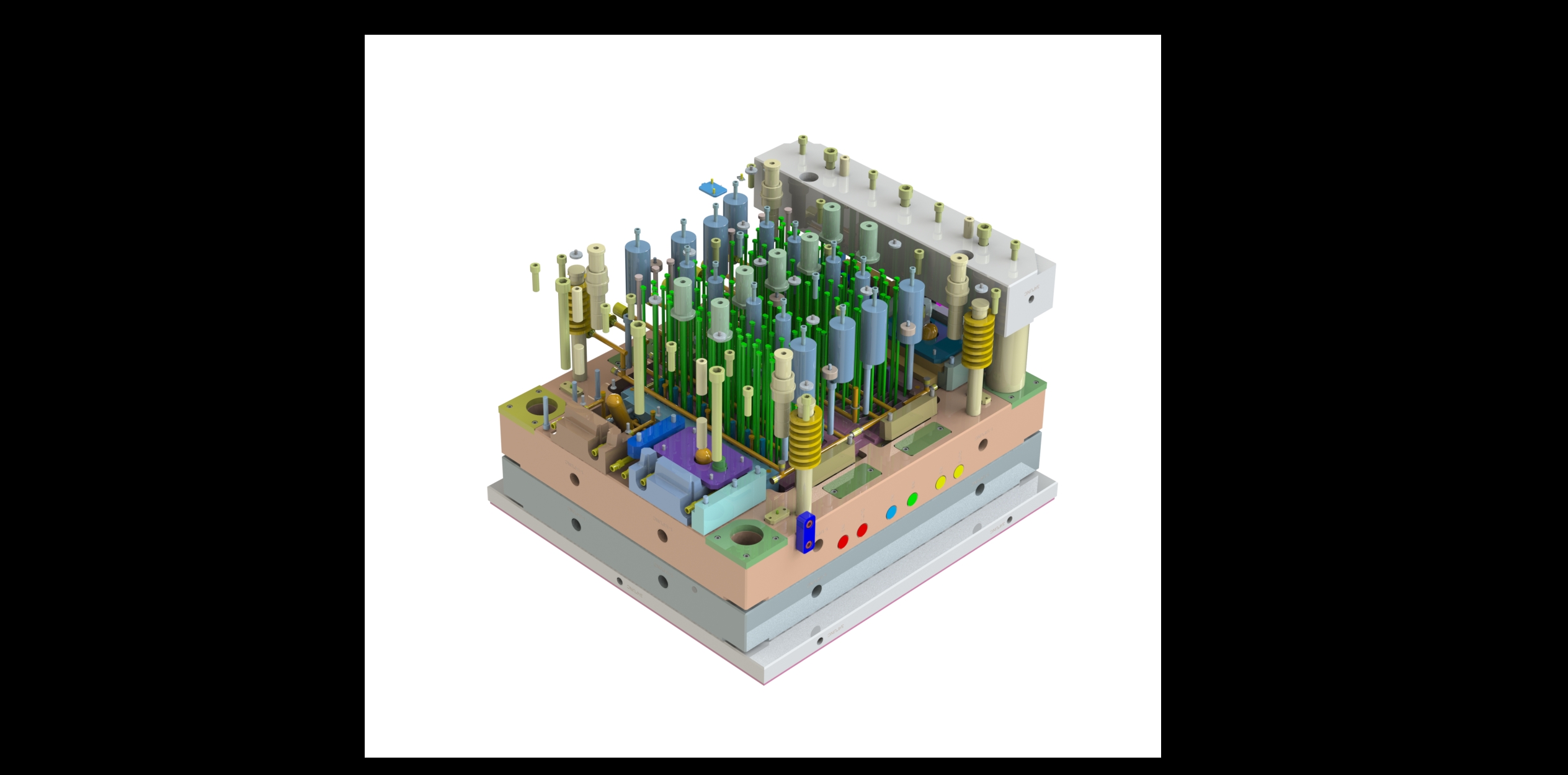

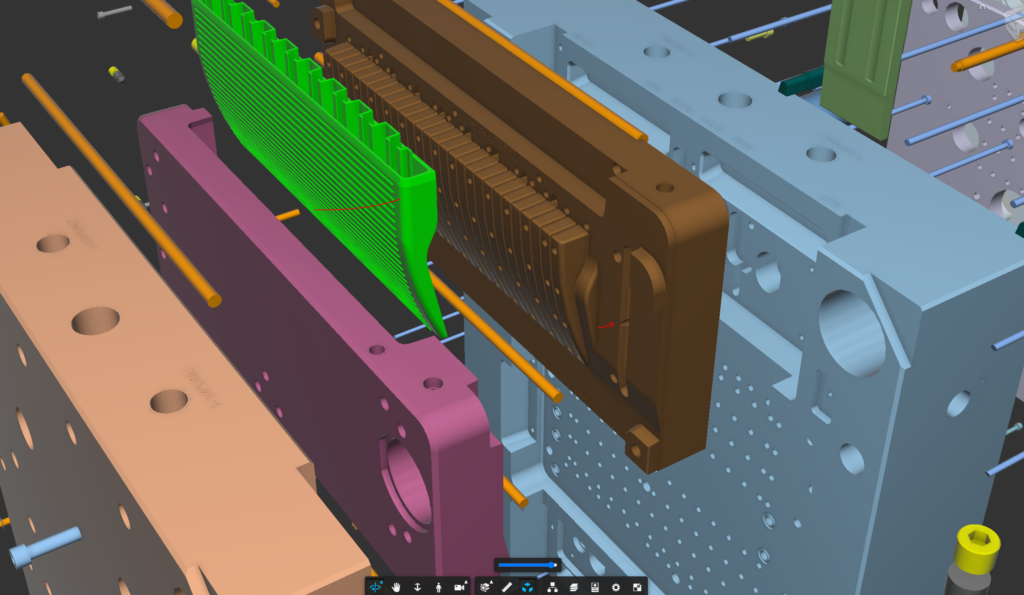

3D MOLD MODEL CUSTOMER APPROVAL

ORDERING STEEL MOLD BASE

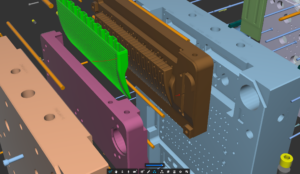

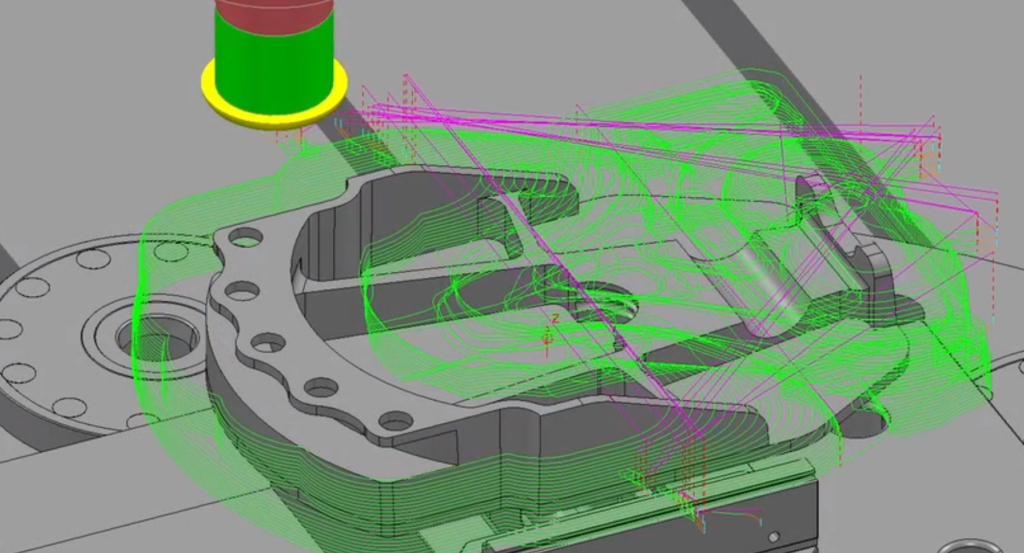

CNC PROGRAMMING MOLD AND ELECTRODES

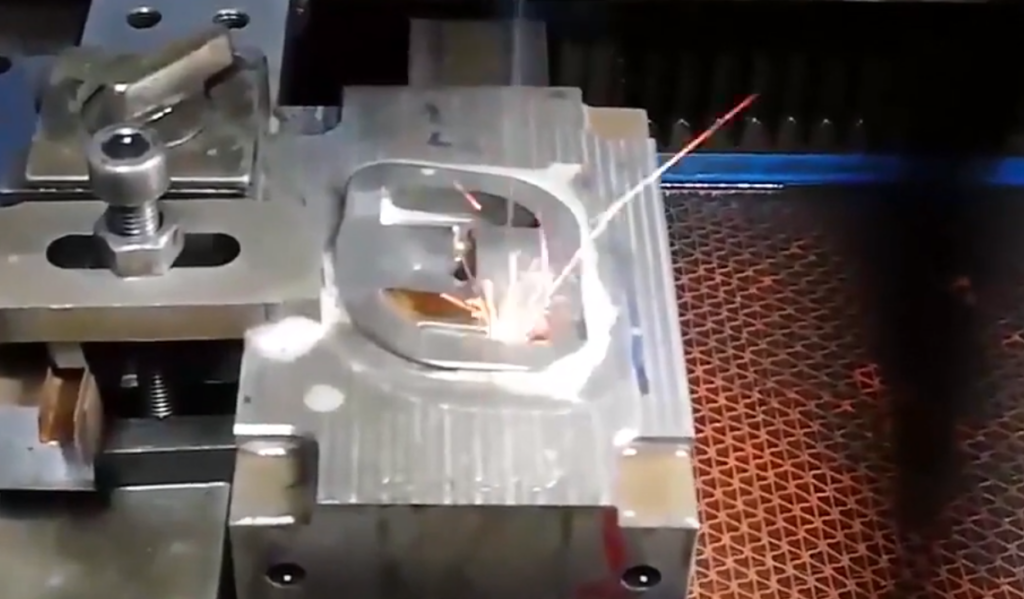

WIRE EDM OF CRITICAL COMPONENTS

ELECTRODE MACHINING

ROUGH AND PRECISE MACHINING

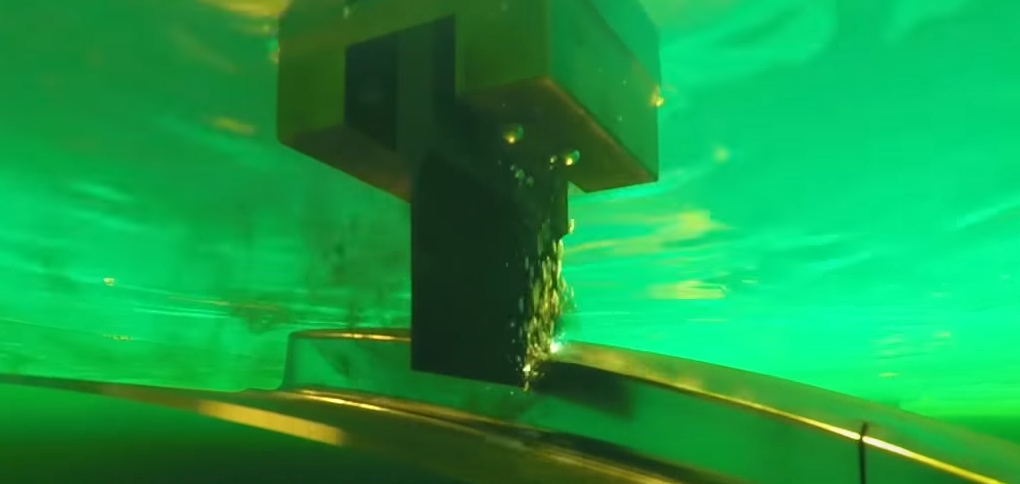

ELECTRODE PUNGE FOR PRECISION GEOMETRY

FINE POLISHING OF GLOSS FINISH SURFACES

EDM PLUNGE FOR DETAILS AND TEXTURE SURFACES

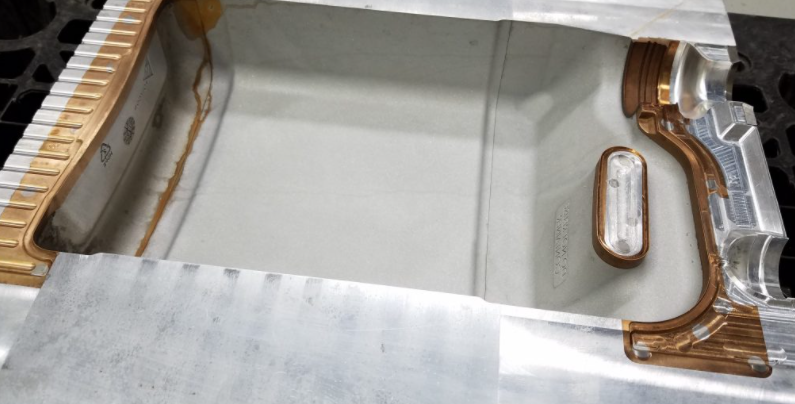

MATCH MATE PARTING LINE ADJUSTMENTS

HEAT TREATMENT OF CORES AND CAVITIES

FINAL ASSEMBLY OF MOLD COMPONENTS

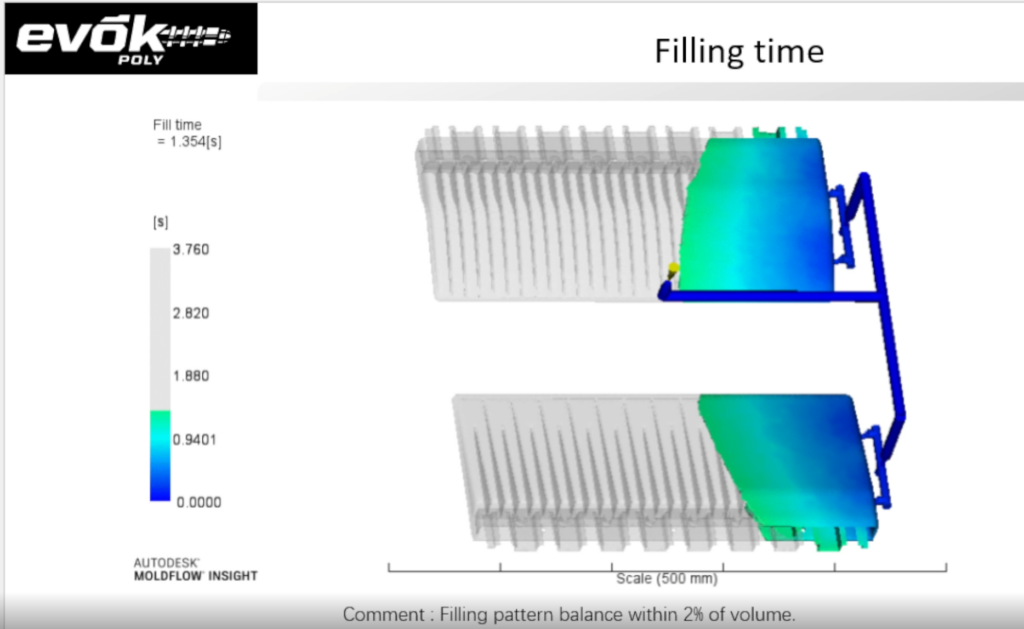

POLY MATERIAL PREP

T1 TRIAL

SAMPLE INSPECTION

MOLD ADJUSTMENT

T2 2nd TRIAL

ADD TEXTURE /POLISH

MOLD SHIPPING

FIRST ARTICLE APPROVAL

PRODUCTION

UNDERSTANDING WHAT TOOLING TYPE BEGINS WITH UNDERSTANDING YOUR VOLUMES AND YOUR TIMELINE

EVOK ONLY FOCUSES ON PRODUCTION TOOLING ALTHOUGH WE KNOW EVALUATION TOOLING AND SHORT RUN TOOLING IS SOMETIMES THE BEST OPTION WHEN EVALUATING PART PERFORMANCE OR MARKET ACCEPTANCE.

SOLUTIONS

We run a lean “TRUST BASED PROCESS” where you control the variables.

GET STARTED

Reach out to us and get full access to our Polyestimator!